What Is PLA?

SelfEco products are made from PLA (polylactic acid) — a renewable, plant-based bioplastic. Derived from U.S.-grown corn, sugar beets, and switchgrass, PLA is a starch-based material that looks, feels, and performs like traditional plastic, but with one major difference: it’s 100% compostable in commercial composting facilities.

From cups, plates, and bowls to cutlery and catering supplies, we use PLA across our entire line of compostable partyware to offer a cleaner, smarter alternative to petroleum-based plastics.

Why We Use PLA

SelfEco products are made from PLA (polylactic acid) — a renewable, plant-based bioplastic. Derived from U.S.-grown corn, sugar beets, and switchgrass, PLA is a starch-based material that looks, feels, and performs like traditional plastic, but with one major difference: it’s 100% compostable in commercial composting facilities.

From cups, plates, and bowls to cutlery and catering supplies, we use PLA across our entire line of compostable partyware to offer a cleaner, smarter alternative to petroleum-based plastics.

- Compostable in commercial facilities

- Petroleum-free and BPA-free

- Durable and event-ready

- Lowers greenhouse gas emissions

- Perfect for catering, foodservice, and eco events

PLA vs. Traditional Plastic

Side-by-side comparison table (PLA vs. petroleum-based plastic):

| SelfEco (PLA) | Traditional Plastic | |

|---|---|---|

| Material Source | Made from renewable U.S.-grown plants (corn, sugar beets) | Made from nonrenewable petroleum |

| End of Life | 100% compostable in commercial facilities | Landfilled or incinerated |

| Carbon Footprint | Lower greenhouse gas emissions | High emissions during production |

| Safety | BPA-free, FDA-approved for food contact | May contain harmful chemicals |

| Manufacturing | Proudly made in the USA | Often imported with limited oversight |

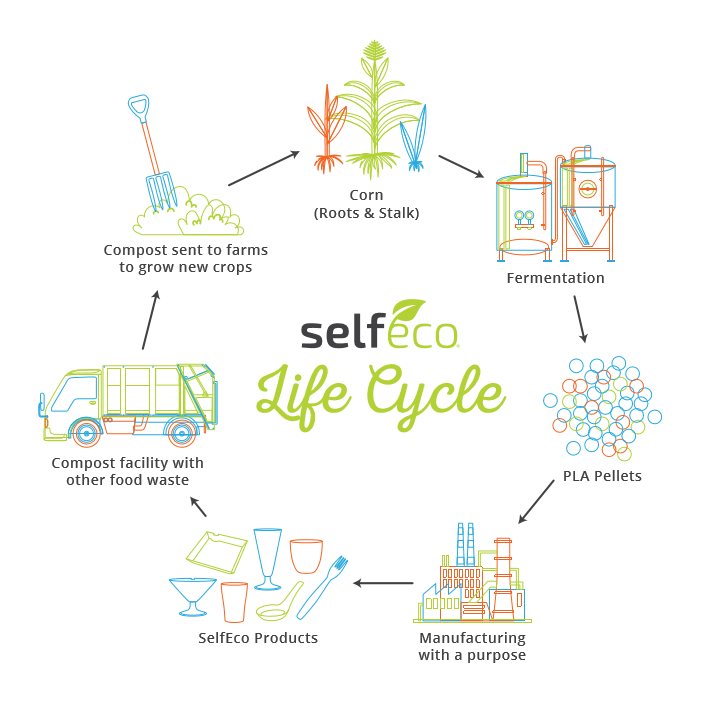

Closing the Loop

Composting with PLA helps return nutrients to the earth and reduce landfill waste. It’s not just disposable — it’s part of a regenerative cycle.

Where We Source Our PLA

We proudly source our PLA from NatureWorks, LLC, the leading supplier of high-quality, food-safe bioplastics. Their proprietary Ingeo™ biopolymer is made from 100% annually renewable plant sugars and is engineered to match the performance of petroleum-based materials without the environmental cost.